|

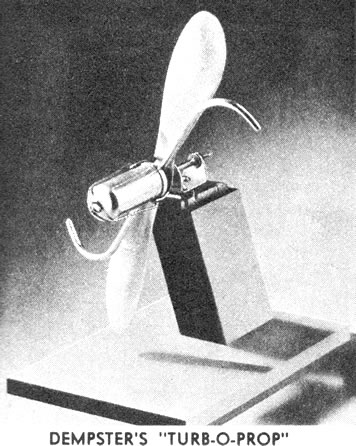

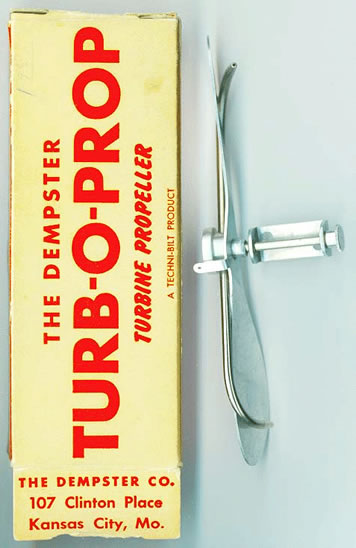

Dempster Turb-O-Prop

The Dempster Turb-O-Prop must surely be a leading contender for the title of Most Fiendishly Imaginative Application of Jetex Power. It was greeted by Flying Models in February 1955 with this notice:

THE DEMPSTER CO. (Kansas City, Mo.) is now distributing the new Turbo-Prop [sic] – a powered propeller driven by an integral rocket-type motor which releases its exhaust gasses [sic] through two curved turbine tubes. The principal [sic] of operation is the burning of two Jetex 50 capsules in a chamber that rotates with the propeller. The prop, jet tubes, combustion chamber and shaft all rotate as one unit.

Running time is approximately 20 seconds, after which the unit is free to spin – creating only a slight drag. The manufacturer suggests use of this power plant on model planes up to 1/2 A size. It sells for $3.98.

Alistair Simpson, who contributed the material from Flying Models, observes: "In addition to the limited likelihood that the device could ever fly a model, at the advertised price of $3.98 the Turb-O-Prop was expensive too – 16 times the 25c cover price of Flying Models at the time. If the mag price equates to a present day typical magazine cover price of £3 sterling ($6 US), that would equate now to about £48 sterling, or $96! In 1954 an 049 OK Cub Model B outfit or an 049 Cox Space Bug Jr could be had from American Hobby Center for less money ($3.95). No need to look far for reasons for lack of commercial success!" [One sold on eBay in November 2002 for $US170.50.]

After studying the Turb-O-Prop more closely (but without any indication that they'd actually tried it to power a flying model), Flying Models published the following review in April 1955:

TURB-O-PROP

Turb-O-Prop is the trade name for a new form of model plane power – a jet-driven propeller using solid rocket fuel for thrust. The fuel used is one or two capsules of the Jetex No. 50 type. Burning this fuel produces high velocity gases, which are exhausted through two jet tubes to provide thrust to rotate a 6" diameter aluminum propeller. Depending upon the fuel used and rate of fuel burning, the total engine run is approximately 30 seconds. During this time, sufficient thrust is developed to fly a regular 1/2A freeflight model. Weight of the complete engine, less fuel, is ¾ of an ounce. Static thrust of the prop is about 2 ounces, r.p.m.'s are approx. 4,000.

Along with the instant-starting features of this type of engine, there is a complete absence of torque. This allows the prop to be used on small models and, when combined with low weight, should give phenomenal flight performance.

The propeller is free-wheeling, of course, when power is exhausted. No moving parts are heavily loaded, therefore the engine, with proper care, should have a very long life. Mounting on models is by means of a short mounting bracket which has two holes for wood screws or machine bolts.

The propeller itself is blanked from .032" aluminum. It is 6" in diameter, and of approximately 8" pitch. The propeller has two tabs with holes to retain the combustion chamber clip.

A turned aluminum-alloy hub is used to mount the jet tube and main shaft. The prop slide-fits on the hub. The combustion-chamber mounting gasket is seated in a turned portion of the hub. The jet tube is ¹/8" O.D. plated brass tubing which is curved to follow the prop pitch, with each end formed to provide a small jet nozzle.

The main shaft is ¹/8" O.D. plated brass tubing, with internal threads at the outer end to receive a bolt, and with a small hole near the same end through which the Jetex fuse is extended. The bolt is made of steel, with a pressed-on knurled aluminum knob.

The combustion chamber is a deepdrawn piece of aluminum, 1 9/16" in length and 5/8" O.D. It has a small indentation on the forward end to retain the spring clip. This retaining clip is formed from .040" piano wire.

The mounting bracket is bent from aluminum alloy sheet and has two pressed-in brass eyelets as bearings.

Regular Jetex No. 50 fuel capsules, screens, gaskets and fuses can be used, but the gasket should be not over .025" in thickness for positive sealing. A minimum of 4" of fuse should be used. The fuse should be put through the small hole in the main shaft near the knurled bolt end, and then coiled several times against the face of the fuel charge before the screen is pressed into place. The spring clip should be put in its correct place after properly fitting the combustion chamber against the gasket. The knurled bolt should be partially screwed in before lighting the fuse, then screwed in fully after the fuse has burned through the small hole. Turb-0-Prop should be treated with the same respect as a 1/2A engine.

It requires adequate bolting down before running, should only be run out of doors because of the gases produced and should not be held while running nor until it has cooled.

Turb-O-Prop is of course easy to start. It requires cleaning after each run because the combustion produces small amounts of material which, combined with moisture from the air, can in a few hours form corroding substances. Wooden sticks and pipe cleaners can be used to prevent scoring of the sealing surfaces, and fine wire can be used to clean the jet tubes.

Price of the Turb-O-Prop – complete with prop, combustion chamber with gasket and mounting bracket – is $3.98.

|

|

- Flying Models, February 1955 (p. 7)

- Air Trails, December 1954 (p. 57)

- Edward Jones

Turb-O-Prop instruction sheet

Turb-O-Prop instruction sheet

|